Phone

+86-15858625699

1. Integrated design, compared with traditional assembled variable frequency water pumps, is more beautiful, atmospheric, and upscale.

2. The water pass parts meet the drinking water standards and provide healthy water usage.

3. Equipped with a diaphragm pressure tank, and butyl (II1R) membrane, air permeability is 1/7 of traditional rubber, steam permeability is 1/200 of traditional rubber, and lifetime is extended by 10 times.

4. Equipped with American imported Sensata vehicle grade pressure sensors, with higher sensing accuracy and more reliable performance.

5. Equipped with automotive-grade waterproof bearings, the noise is reduced, allowing the motor to easily cope with harsh environments such as high temperature and humidity, effectively reducing the frequency and time cost of product after-sales service.

6. Equipped with comprehensive protection functions, including over temperature, over-current, over-voltage, anti-freezing, and water shortage protection measures, the product is truly intelligent, worry-free, and durable.

7. Complete communication capabilities, equipped with self-organizing network or remote control functions, easily responding to various needs and challenges.

8. Equipped with the most advanced variable frequency speed regulation technology and harmonic processing design, it effectively improves the efficiency of electricity use, reduces high-frequency noise caused by harmonics, and makes the product more quite and more energy-efficient.

Technical data

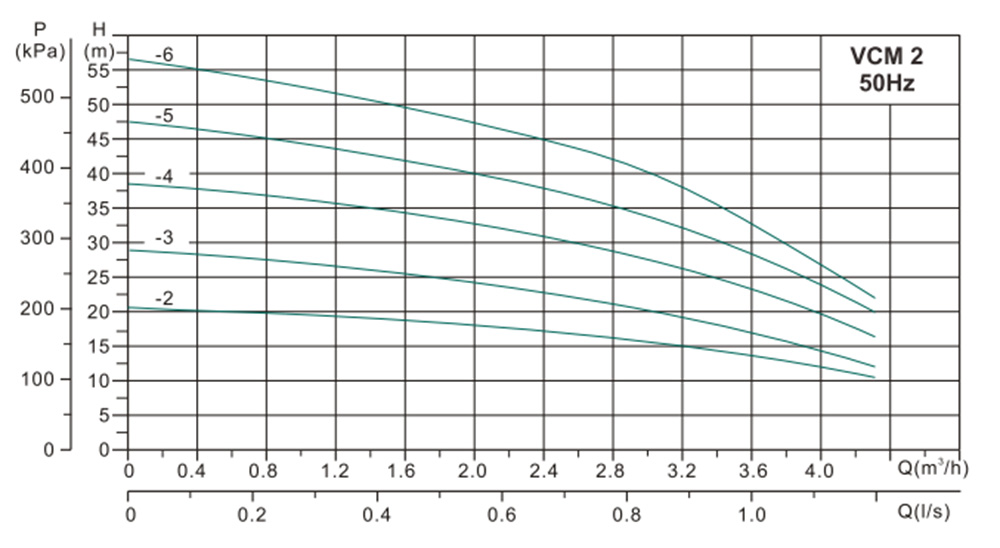

| MODEL | Driving motor P₂ (kW) | Q(m³/h) | 0.8 | 1.2 | 1.6 | 2 | 2.4 | 2.8 | 3.2 | 3.6 | 4 |

| VCM2-2 | 0.25 | H(m) | 19 | 19 | 18 | 18 | 17 | 16 | 14 | 13 | 12 |

| VCM2-3 | 0.37 | 27 | 26 | 25 | 24 | 23 | 22 | 20 | 17 | 15 | |

| VCM2-4 | 0.55 | 36 | 35 | 34 | 32 | 31 | 29 | 27 | 23 | 20 | |

| VCM2-5 | 0.55 | 44 | 43 | 42 | 40 | 38 | 36 | 33 | 28 | 24 | |

| VCM2-6 | 0.75 | 53 | 51 | 49 | 47 | 44 | 41 | 37 | 32 | 27 |

Performance curve

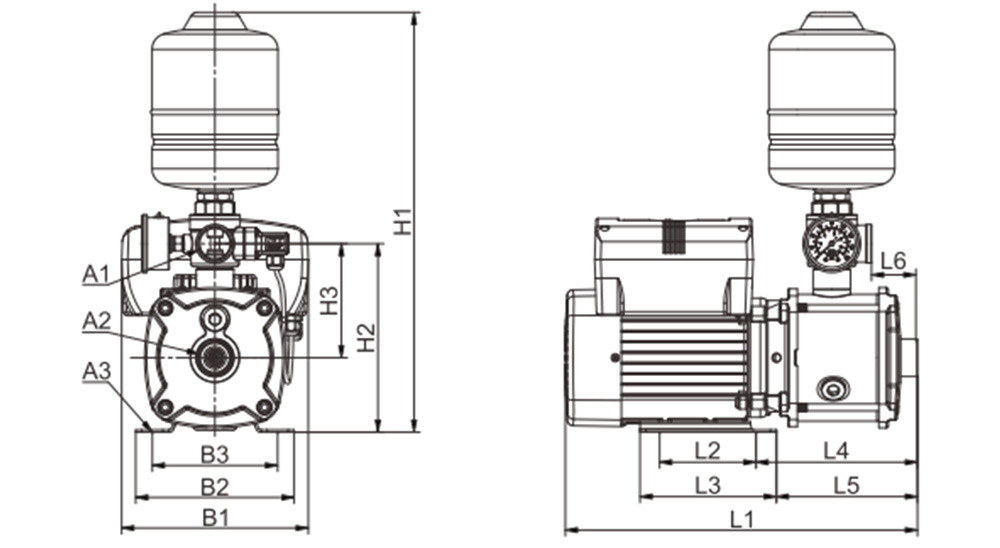

Installation sketch

| MODEL | Dimensions(mm) | Weight(kg) | ||||||||||||||

| A1 | A2 | A3 | B1 | B2 | B3 | H1 | H2 | H3 | L1 | L2 | L3 | L4 | L5 | L6 | ||

| VCM2-2 | G1 | G1 | 11 | 186 | 158 | 125 | 420 | 188 | 114 | 316 | 96 | 136 | 125 | 105 | 45 | 8.9 |

| VCM2-3 | G1 | G1 | 11 | 186 | 158 | 125 | 420 | 188 | 114 | 334 | 96 | 136 | 143 | 123 | 45 | 9.1 |

| VCM2-4 | G1 | G1 | 11 | 186 | 158 | 125 | 420 | 188 | 114 | 352 | 96 | 136 | 161 | 141 | 45 | 11.3 |

| VCM2-5 | G1 | G1 | 11 | 186 | 158 | 125 | 420 | 188 | 114 | 370 | 96 | 136 | 179 | 159 | 45 | 12 |

| /CM2-6 | G1 | G1 | 11 | 186 | 158 | 125 | 420 | 188 | 114 | 388 | 96 | 136 | 197 | 177 | 45 | 13.6 |

Technical data

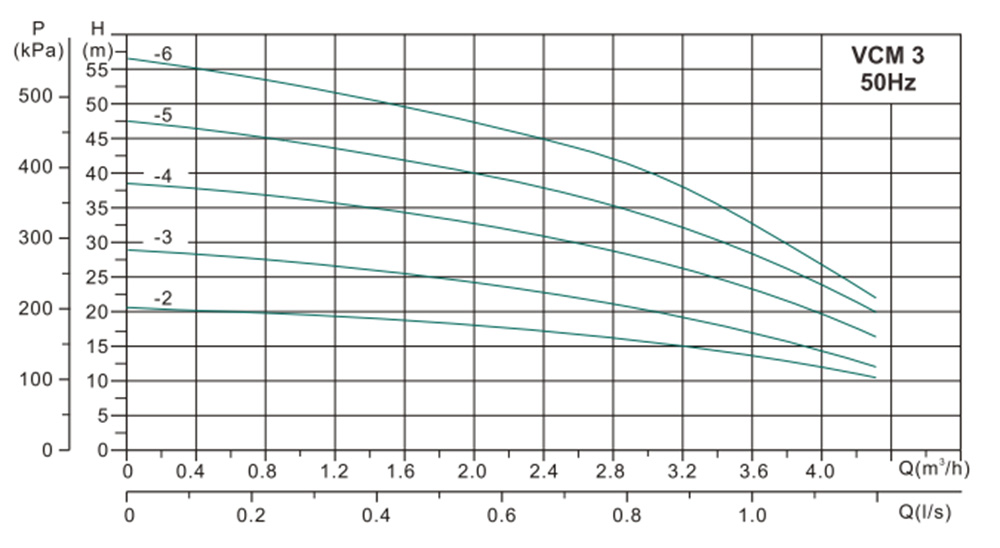

| MODEL | Driving motor P₂ (kW) | Q(m³/h) | 0.8 | 1.2 | 1.6 | 2 | 2.4 | 2.8 | 3 | 3.2 | 3.6 | 4 |

| VCM3-2 | 0.25 | H(m) | 19 | 19 | 18 | 18 | 17 | 16 | 15 | 14 | 13 | 12 |

| VCM3-3 | 0.37 | 27 | 26 | 25 | 24 | 23 | 22 | 21 | 20 | 17 | 15 | |

| VCM3-4 | 0.55 | 36 | 35 | 34 | 32 | 31 | 29 | 28 | 27 | 23 | 20 | |

| VCM3-5 | 0.55 | 44 | 43 | 42 | 40 | 38 | 36 | 34 | 33 | 28 | 24 | |

| VCM3-6 | 0.75 | 53 | 51 | 48 | 47 | 45 | 41 | 38 | 36 | 31 | 27 |

Performance curve

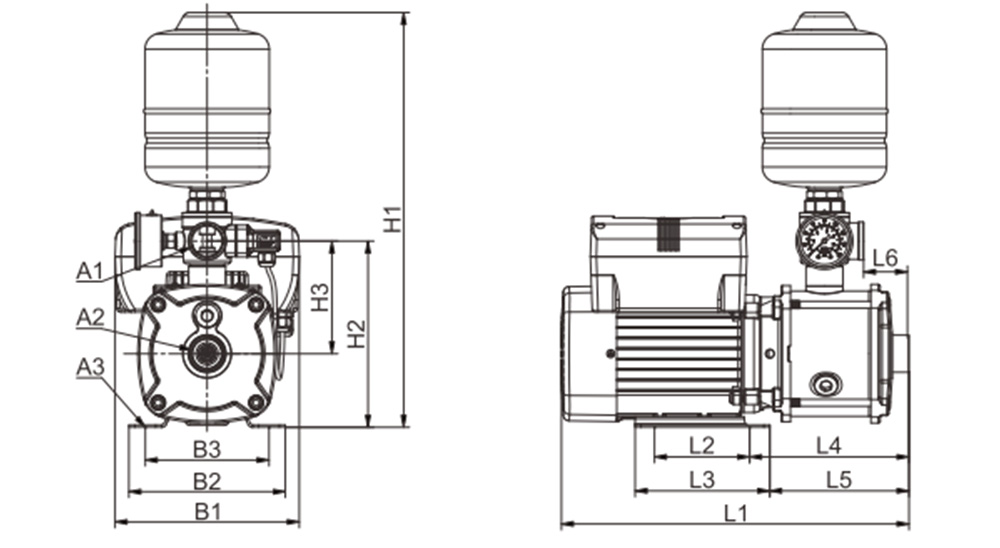

Installation sketch

| MODEL | Dimensions(mm) | Weight(kg) | ||||||||||||||

| A1 | A2 | A3 | B1 | B2 | B3 | H1 | H2 | H3 | L1 | L2 | L3 | L4 | L5 | L6 | ||

| VCM3-2 | G1 | G1 | 11 | 186 | 158 | 125 | 420 | 188 | 114 | 316 | 96 | 136 | 125 | 105 | 45 | 8.9 |

| VCM3-3 | G1 | G1 | 11 | 186 | 158 | 125 | 420 | 188 | 114 | 334 | 96 | 136 | 143 | 123 | 45 | 9.1 |

| VCM3-4 | G1 | G1 | 11 | 186 | 158 | 125 | 420 | 188 | 114 | 352 | 96 | 136 | 161 | 141 | 45 | 11.3 |

| VCM3-5 | G1 | G1 | 11 | 186 | 158 | 125 | 420 | 188 | 114 | 370 | 96 | 136 | 179 | 159 | 45 | 12 |

| VCM3-6 | G1 | G1 | 11 | 186 | 158 | 125 | 420 | 188 | 114 | 388 | 96 | 136 | 197 | 177 | 45 | 13.6 |

Technical data

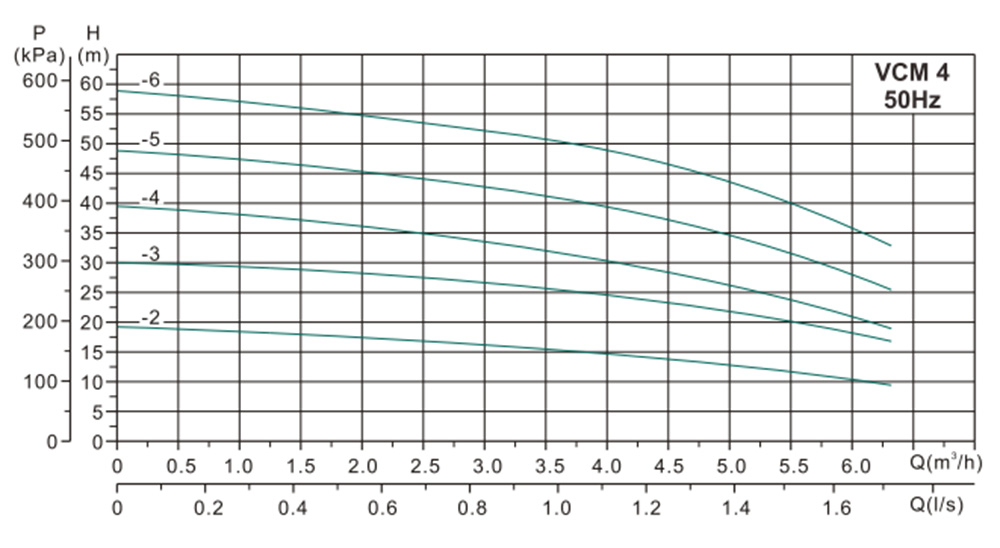

| MODEL | Driving motor P₂ (kW) | Q(m³/h) | 1 | 1.5 | 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 5.5 | 6 |

| VCM4-2 | 0.37 | H(m) | 18 | 18 | 17 | 17 | 16 | 15 | 15 | 13 | 13 | 11 | 10 |

| VCM4-3 | 0.55 | 29 | 28 | 28 | 27 | 26 | 25 | 25 | 23 | 22 | 20 | 18 | |

| VCM4-4 | 0.75 | 38 | 37 | 36 | 34 | 33 | 32 | 30 | 28 | 27 | 24 | 20 | |

| VCM4-5 | 1 | 47 | 46 | 45 | 44 | 42 | 41 | 40 | 36 | 35 | 32 | 27 | |

| VCM4-6 | 1.3 | 56 | 55 | 54 | 53 | 52 | 51 | 49 | 45 | 44 | 42 | 36 |

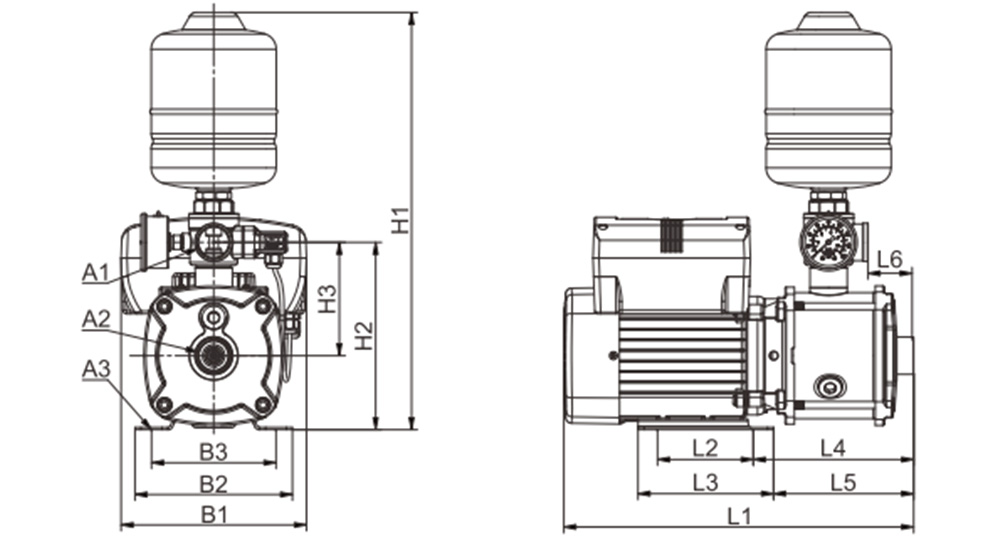

Performance curve

Installation sketch

| MODEL | Dimensions(mm) | Weight( kg) | ||||||||||||||

| A1 | A2 | A3 | B1 | B2 | B3 | H1 | H2 | HB | L1 | L2 | L3 | L4 | L5 | L6 | ||

| VCM4-2 | G1 | G1% | 11 | 186 | 158 | 125 | 420 | 188 | 114 | 316 | 96 | 136 | 125 | 105 | 45 | 9.5 |

| VCM4-3 | G1 | G1% | 11 | 186 | 158 | 125 | 420 | 188 | 114 | 334 | 96 | 136 | 143 | 123 | 45 | 11.3 |

| VCM4-4 | G1 | G1% | 11 | 186 | 158 | 125 | 420 | 188 | 114 | 352 | 96 | 136 | 161 | 141 | 45 | 12.8 |

| VCM4-5 | G1 | G1% | 11 | 186 | 158 | 125 | 420 | 188 | 114 | 370 | 96 | 136 | 179 | 159 | 45 | 13.4 |

| VCM4-6 | G1 | G1% | 11 | 186 | 158 | 125 | 420 | 188 | 114 | 413 | 96 | 136 | 197 | 177 | 45 | 15.2 |

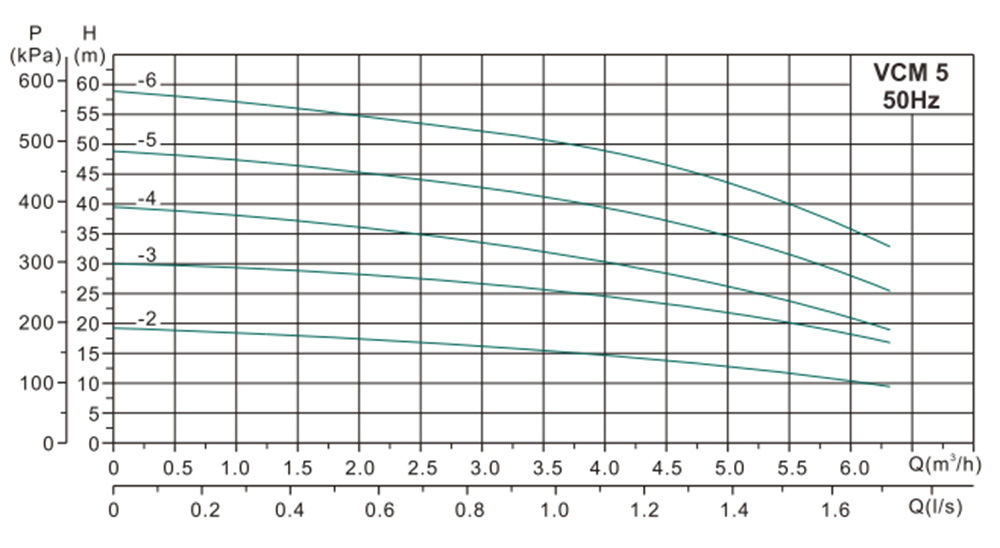

Technical data

| MODEL | Driving motor P₂ (kW) | Q (m³/h) |

1 | 1.5 | 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 5.5 | 6 |

| VCM5-2 | 0.37 | H(m) | 18 | 18 | 17 | 17 | 16 | 15 | 15 | 13 | 13 | 11 | 10 |

| VCM5-3 | 0.55 | 29 | 28 | 28 | 27 | 26 | 25 | 25 | 23 | 22 | 20 | 18 | |

| VCM5-4 | 0.75 | 38 | 37 | 36 | 34 | 33 | 32 | 30 | 28 | 27 | 24 | 20 | |

| VCM5-5 | 1 | 47 | 46 | 45 | 44 | 42 | 41 | 40 | 36 | 35 | 32 | 27 | |

| VCM5-6 | 1.3 | 56 | 55 | 54 | 53 | 52 | 51 | 49 | 45 | 44 | 42 | 36 |

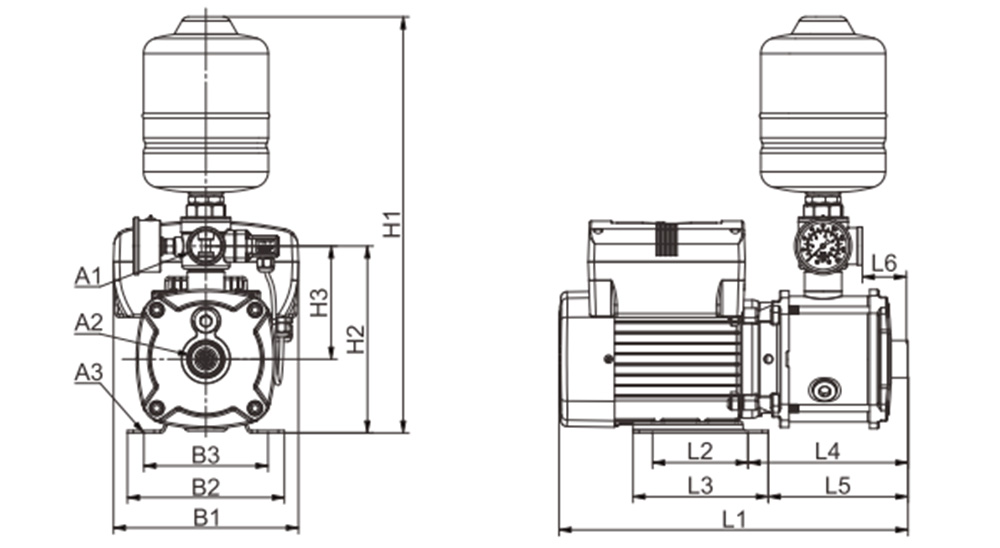

Performance curve

Installation sketch

| MODEL | Dimensions(mm) | Weight(kg) | ||||||||||||||

| A1 | A2 | A3 | B1 | B2 | B3 | H1 | H2 | H3 | L1 | L2 | L3 | L4 | L5 | L6 | ||

| VCM5-2 | G1 | G1% | 11 | 186 | 158 | 125 | 420 | 188 | 114 | 316 | 96 | 136 | 125 | 105 | 45 | 9.5 |

| VCM5-3 | G1 | G1% | 11 | 186 | 158 | 125 | 420 | 188 | 114 | 334 | 96 | 136 | 143 | 123 | 45 | 11.3 |

| VCM5-4 | G1 | G1% | 11 | 186 | 158 | 125 | 420 | 188 | 114 | 352 | 96 | 136 | 161 | 141 | 45 | 12.8 |

| VCM5-5 | G1 | G1% | 11 | 186 | 158 | 125 | 420 | 188 | 114 | 370 | 96 | 136 | 179 | 159 | 45 | 13.4 |

| VCM5-6 | G1 | G1% | 11 | 186 | 158 | 125 | 420 | 188 | 114 | 413 | 96 | 136 | 197 | 177 | 45 | 15.2 |

Technical data

| MODEL | Driving motor P₂ (kW) | Q (m³/h) |

4 | 6 | 8 | 10 | 12 | 14 | 16 |

| VCM8-2 | 0.75 | H (m) |

22 | 20 | 19 | 18 | 13 | 11 | 8 |

| VCM8-3 | 1.1 | 31 | 29 | 26 | 24 | 20 | 16 | 11 | |

| VCM8-4 | 1.5 | 41 | 39 | 37 | 33 | 28 | 23 | 17 | |

| VCM8-4B | 2.2 | 51 | 49 | 46 | 42 | 37 | 30 | 23 |

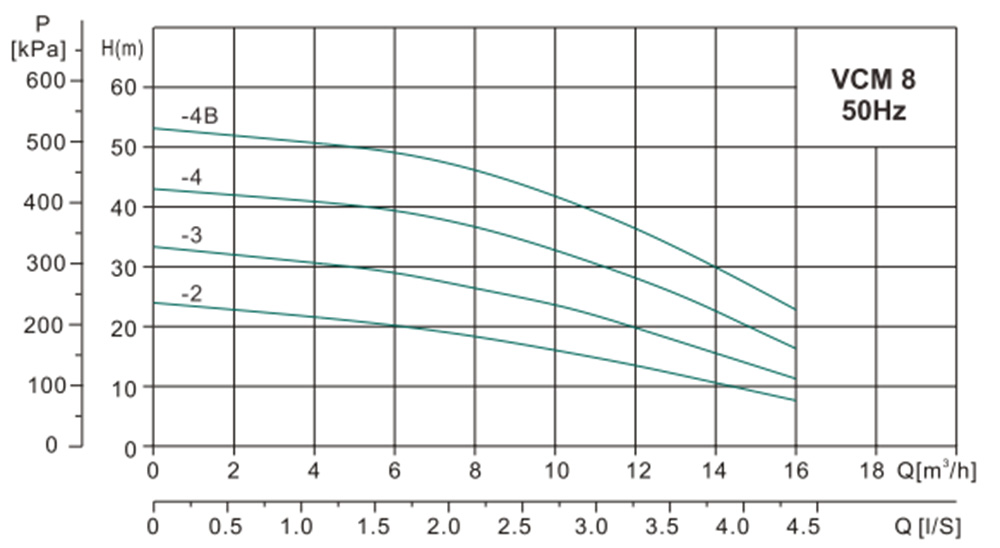

Performance curve

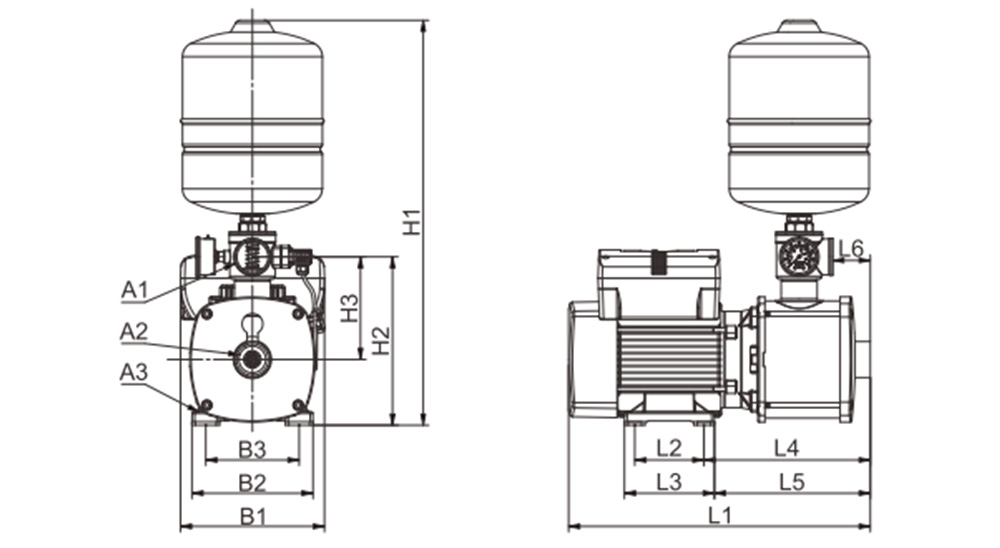

Installation sketch

| MODEL | Dimensions(mm) | Weight(kg) | ||||||||||||||

| A1 | A2 | A3 | B1 | B2 | B3 | H1 | H2 | H3 | L1 | L2 | L3 | L4 | L5 | L6 | ||

| VCM8-2 | G1.5 | G1.5 | 10 | 208 | 175 | 142 | 586 | 243 | 148 | 436 | 100 | 130 | 240 | 225 | 54 | 19.2 |

| VCM8-3 | G1.5 | G1.5 | 10 | 208 | 175 | 142 | 586 | 243 | 148 | 436 | 100 | 130 | 240 | 225 | 54 | 21.8 |

| VCM8-4 | G1.5 | G1.5 | 10 | 208 | 175 | 142 | 586 | 243 | 148 | 466 | 100 | 130 | 240 | 255 | 84 | 23.5 |

| VCM8-4B | G1.5 | G1.5 | 10 | 208 | 175 | 142 | 586 | 243 | 148 | 466 | 100 | 130 | 240 | 255 | 84 | 25.6 |

Technical data

| MODEL | Driving motor P₂ (kW) | Q (m³/h) |

7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| VCM12-2 | 1.1 | H (m) |

23 | 22 | 22 | 21 | 20 | 19 | 18 | 17 | 15 | 13 |

| VCM12-3 | 1.85 | 35 | 34 | 33 | 32 | 31 | 29 | 28 | 26 | 23 | 20 | |

| VCM12-4 | 2.2 | 47 | 46 | 45 | 43 | 41 | 39 | 37 | 35 | 31 | 27 |

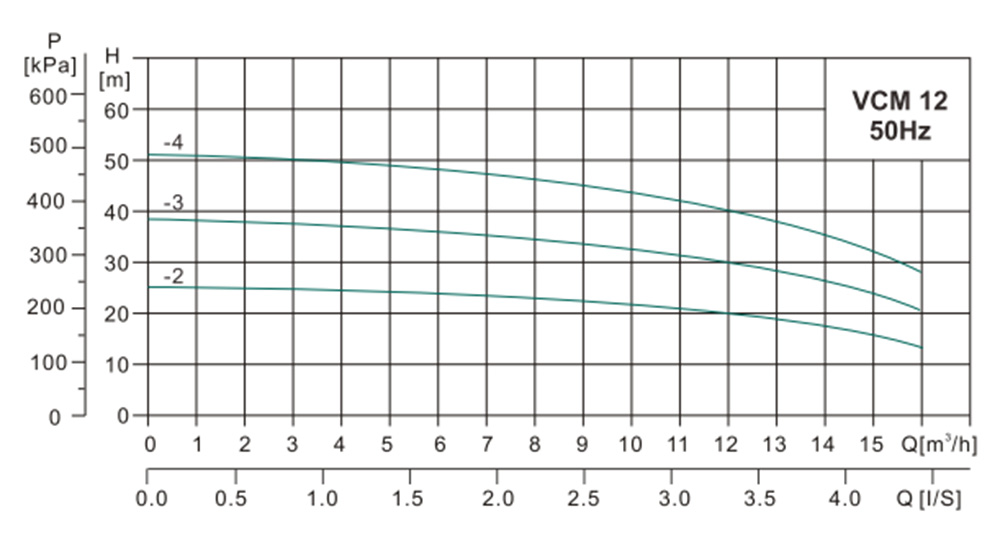

Performance curve

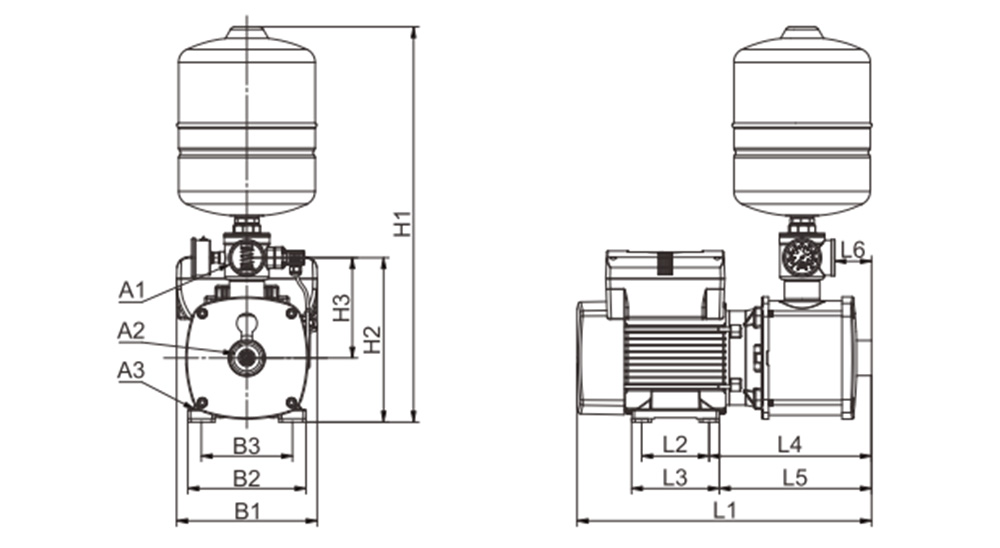

Installation sketch

| MODEL | Dimensions(mm) | Weight(kg) | ||||||||||||||

| A1 | A2 | A3 | B1 | B2 | B3 | H1 | H2 | H3 | L1 | L2 | L3 | L4 | L5 | L6 | ||

| VCM12-2 | G2 | G2 | 10 | 208 | 175 | 142 | 586 | 243 | 148 | 436 | 100 | 130 | 240 | 225 | 54 | 22.1 |

| VCM12-3 | G2 | G2 | 10 | 208 | 175 | 142 | 586 | 243 | 148 | 436 | 100 | 130 | 240 | 225 | 54 | 23.7 |

| VCM12-4 | G2 | G2 | 10 | 208 | 175 | 142 | 586 | 243 | 148 | 466 | 100 | 130 | 240 | 255 | 84 | 25.8 |

Technical data

| MODEL | Driving motor P₂ (kW) | Q (m³/h) |

8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 |

| VCM16-1 | 1.1 | H (m) |

12 | 11.5 | 11 | 10 | 10 | 9 | 8 | 7 | 6 |

| VCM16-2 | 2.2 | 24 | 23 | 22 | 21 | 20 | 19 | 16 | 14 | 12 |

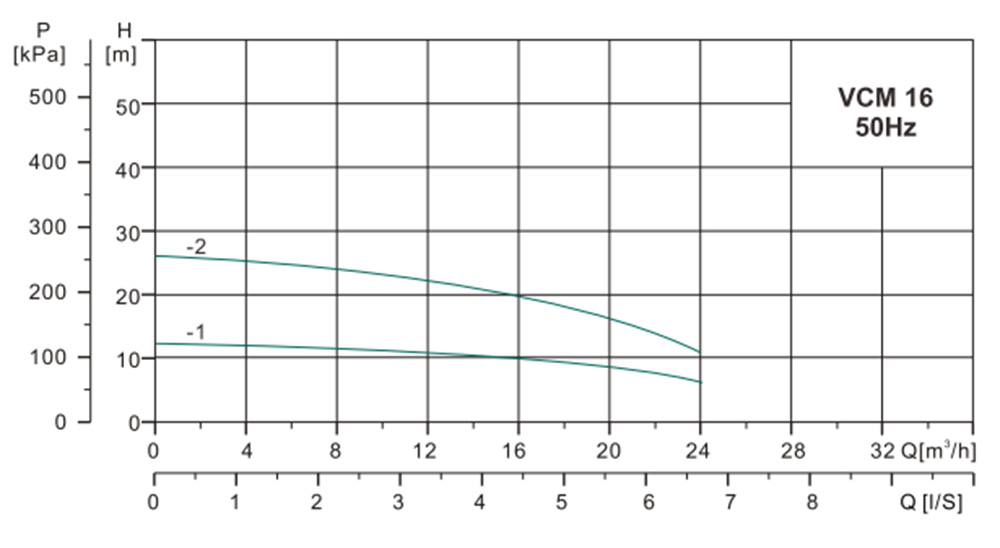

Performance curve

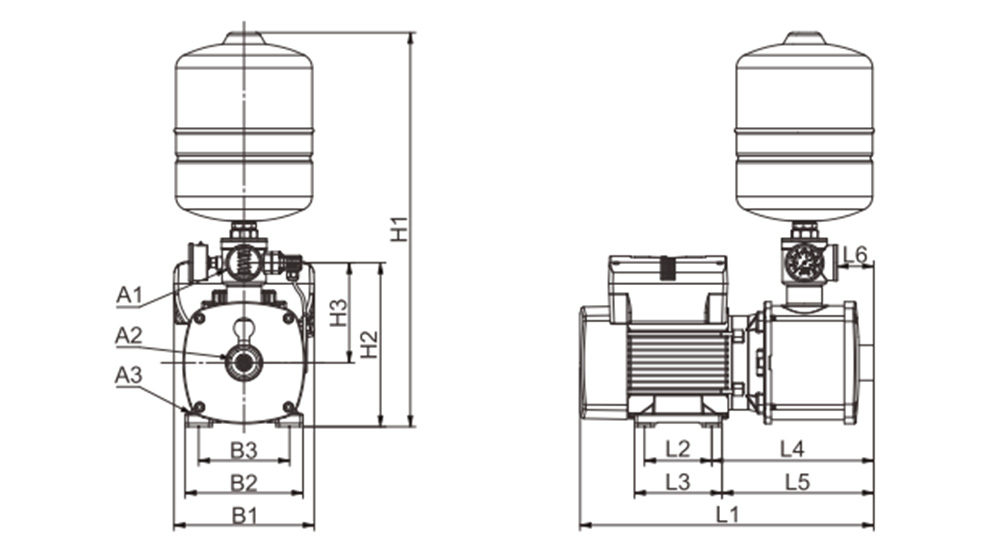

Installation sketch

| MODEL | Dimensions(mm) | Weight(kg) | ||||||||||||||

| A1 | A2 | A3 | B1 | B2 | B3 | H1 | H2 | H3 | L1 | L2 | L3 | L4 | L5 | L6 | ||

| VCM16-1 | G2 | G2 | 10 | 208 | 175 | 142 | 586 | 243 | 148 | 426 | 100 | 130 | 213 | 42 | 21.2 | |

| VCM16-2 | G2 | G2 | 10 | 208 | 175 | 142 | 586 | 243 | 148 | 426 | 100 | 130 | 213 | 42 | 23.5 | |

Technical data

| MODEL | Driving motor P₂ (kW) | Q (m³/h) |

10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 26 | 28 |

| VCM20-1 | 1.1 | H (m) |

13 | 12 | 12 | 11 | 11 | 10 | 10 | 9 | 8 | 7 |

| VCM20-2 | 2.2 | 25 | 24 | 23 | 22 | 21 | 20 | 18 | 16 | 14 | 12 |

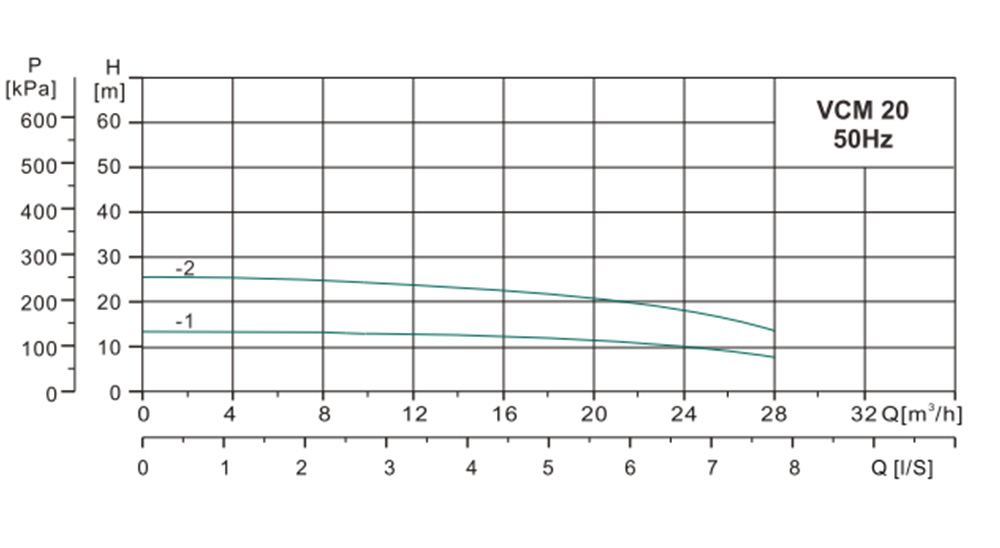

Performance curve

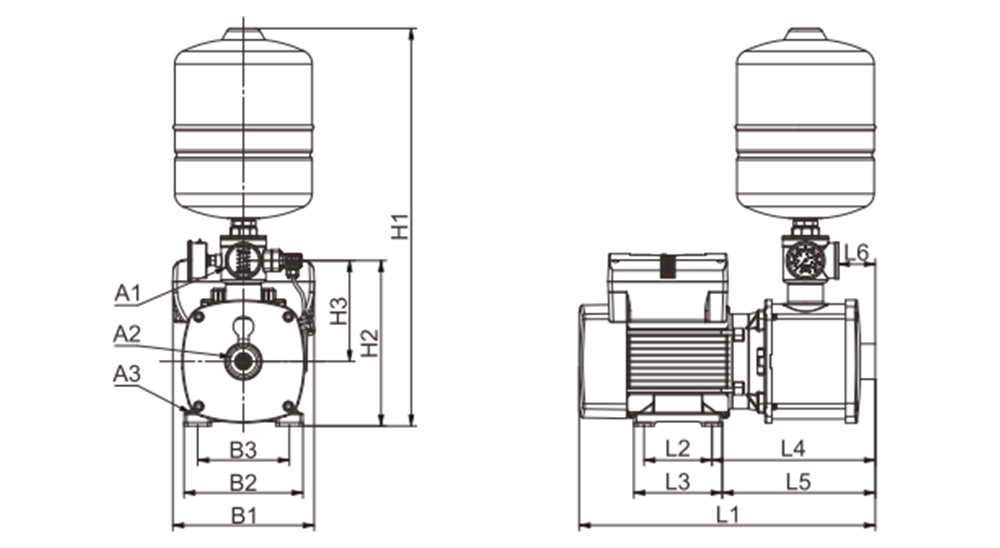

Installation sketch

| MODEL | Dimensions(mm) | Weight(kg) | ||||||||||||||

| A1 | A2 | A3 | B1 | B2 | B3 | H1 | H2 | H3 | L1 | L2 | L3 | L4 | L5 | L6 | ||

| VCM20-1 | G2 | G2 | 10 | 208 | 175 | 142 | 586 | 243 | 148 | 426 | 100 | 130 | 228 | 213 | 42 | 21.5 |

| VCM20-2 | G2 | G2 | 10 | 208 | 175 | 142 | 586 | 243 | 148 | 426 | 100 | 130 | 228 | 213 | 42 | 23.8 |

Contact Us

Your email address will not be published. Required fiels are marked